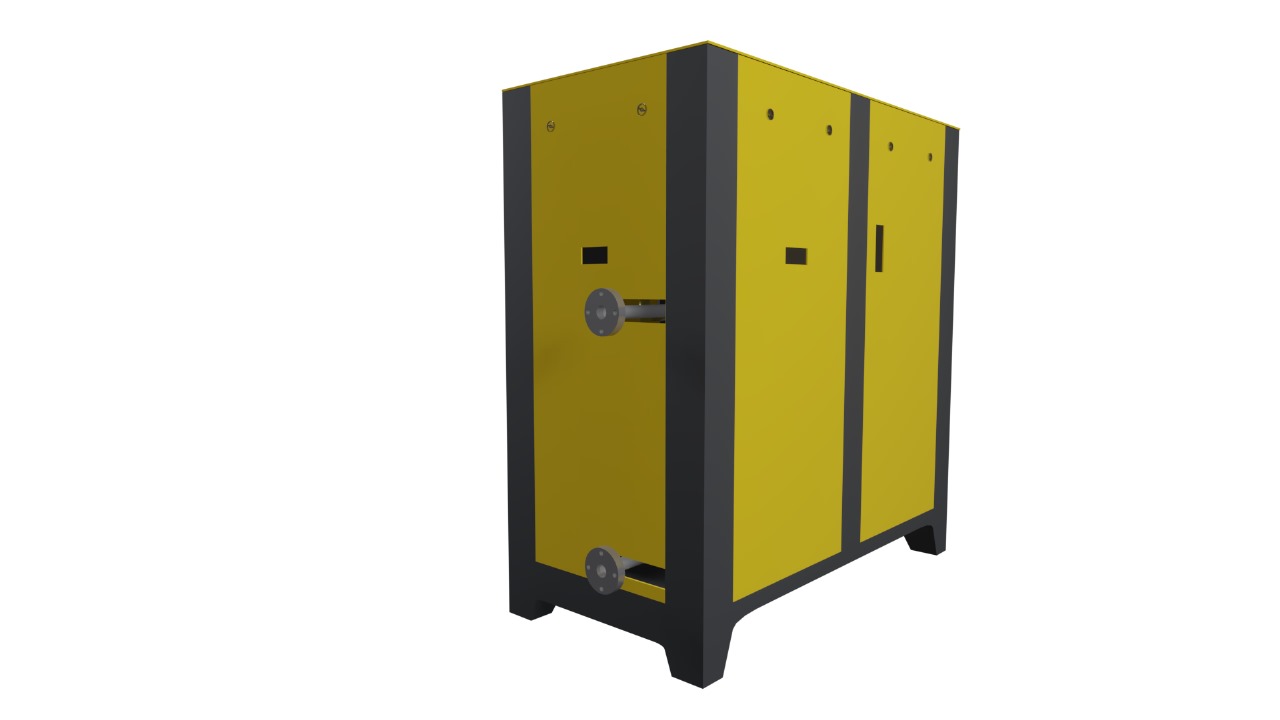

ChillerMate

Save Energy & Generate Hot Water at ₹0.2/kWh

ChillerMate is an innovative desuperheater system that recovers waste heat from your chiller's refrigeration cycle to generate hot water. Achieve 30-40% reduction in heating costs while improving your chiller's cooling efficiency through reduced condenser load.

Why ChillerMate?

Dual benefits - energy savings and improved chiller performance

Energy Savings

Recover waste heat to offset heating costs and reduce overall energy consumption

Improved Chiller Efficiency

Reduced condenser load increases cooling capacity and lowers power consumption

Double-Wall Safety

Refrigerant and water never mix with our fail-safe double-walled design

IoT Monitoring

Remote monitoring provides real-time system performance and energy savings data

Our Process

From assessment to installation - complete end-to-end solution

Data Collection & Assessment

We conduct a comprehensive facility audit to identify waste heat recovery opportunities from your existing chiller systems.

- Chiller capacity analysis

- Hot water demand assessment

- Energy consumption patterns

- ROI calculation and projections

Custom Design & Engineering

Our engineers design a ChillerMate system tailored to your chiller capacity and hot water temperature requirements.

- Custom desuperheater sizing

- Heat exchanger specifications

- Pipeline routing design

- Control system integration

End-to-End Installation

Complete turnkey solution including pipeline installation and heat delivery unit setup for efficient heat transfer.

- Professional installation team

- Pipeline laying and insulation

- Heat delivery unit setup

- System commissioning and testing

Safety & Monitoring

Our double-walled safety system ensures refrigerant and water never mix, while IoT monitoring provides 24/7 system oversight.

- Double-walled heat exchanger

- Real-time performance monitoring

- Automated alerts and notifications

- Remote troubleshooting support

Perfect Applications

Ideal for facilities with both cooling and heating requirements

FMCG Manufacturing

Food processing and beverage facilities with refrigeration and hot water needs.

- Product cooling processes

- Cleaning and sanitization

- Process hot water

- Equipment sterilization

Pharmaceutical Industry

Clean room cooling with hot water for equipment cleaning and process heating.

- Clean room air conditioning

- Equipment cleaning systems

- Process hot water supply

- Facility heating

Commercial Buildings

Office buildings and hotels with central HVAC systems and hot water requirements.

- Central air conditioning

- Hot water for facilities

- Kitchen hot water supply

- Space heating applications

Dairy Processing

Milk cooling and pasteurization with hot water for cleaning and processing.

- Milk chilling systems

- CIP (Clean-in-Place) systems

- Pasteurization preheating

- Equipment sanitization

Cold Storage

Large-scale refrigeration with hot water for defrosting and facility operations.

- Warehouse refrigeration

- Defrosting operations

- Loading dock heating

- Office space heating

Healthcare Facilities

Hospital HVAC systems with hot water for medical equipment and patient care.

- Medical equipment cooling

- Hot water for patient care

- Laundry hot water systems

- Kitchen operations

Technical Specifications

Engineered for optimal performance and reliability

System Specifications

Performance Features

Double-Wall Safety Design

Prevents refrigerant-water mixing even in case of internal tube failure

IoT-Enabled Monitoring

Real-time performance tracking and predictive maintenance alerts

Modular Design

Scalable solution that can be expanded as your facility grows

Corrosion-Resistant Materials

Stainless steel and copper-nickel construction for longevity

Automatic Control System

Self-regulating system optimizes heat recovery based on demand

Performance Metrics

Proven results across diverse applications

Typical savings on hot water heating costs

Improved cooling capacity due to reduced condenser load

Fast return on investment with guaranteed savings

Reliable operation with minimal maintenance

Transform Your Chiller into an Energy Generator

Contact our energy team for a custom ChillerMate assessment and savings calculation